3D Printing and RepRap On the March

That madcap bunch of 3D printer aficionados at the University of Bath, England is at it again. Now they have opened the Digital Manufacturing Lab to showcase the capabilities of RepRap, the 3D printer that can reproduce itself.

That madcap bunch of 3D printer aficionados at the University of Bath, England is at it again. Now they have opened the Digital Manufacturing Lab to showcase the capabilities of RepRap, the 3D printer that can reproduce itself.

RepRap (Replicating Rapid prototyper) is the brainchild of Dr. Adrian Bowyer. This is a low cost, open source rapid prototyping system that can make a broad array of 3D plastic objects from computer-generated designs. The little devils are multiplying. The Digital Manufacturing Lab’s web site reports that there are over 6,000 RepRap machines in use worldwide by individuals and companies.

This isn’t just a hobbyist’s play toy. The Lab’s initiative is focused on using the RepRap technology for business, falling somewhere in between the large high-end printers from companies like Stratasys and cheap open source printers that can only handle simple geometries (like printing chocolates, a handy tool to have on Halloween). Potential RepRap applications include rapid prototyping and the production of parts for a variety of industries such as aerospace, architecture, automotive, dental, fashion, medical and other industries that can use rapidly fabricated objects of small to m edium size.

edium size.

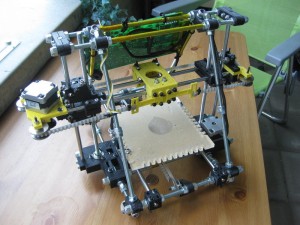

The two latest flavors of the RepRap system on hand at the Digital Manufacturing Lab are the Mendel that can print plastic objects up to 200x200100mm3 at speeds of 15 ml per hour. The Huxley, shown here, is a smaller and more portable machine that can only print 120x120x70 mm, but it’s quicker and can be replicated more easily.

Said Chris DiBona, the open source and public sector engineering manager at Google, “Think of RepRap as a China on your desktop.”

Could there be a RepRap in your future?