Autodesk Weaves the Hyperloop into its Vision of the Future

One month ago, Elon Musk spelled out his dream of a future where a trip from San Francisco to Los Angeles takes a mere 35 minutes thanks to a high-speed train that careens through pneumatic tubes. Now Autodesk has offered its hand in bringing the high speed rail system to life, and has recruited the help of Jordan Brandt, who recently accepted the role of “Technology Futurist,” to design a manufacturing system as advanced as the Hyperloop itself.

In an interview with Digital Manufacturing Report, Brandt explained that his position is a fairly new one at Autodesk, and is a product of changing times for manufacturers.

In an interview with Digital Manufacturing Report, Brandt explained that his position is a fairly new one at Autodesk, and is a product of changing times for manufacturers.

“As a technology futurist in the manufacturing team I’m looking at trends on the near horizon and also the longer-term trends that are impacting the way we design and make things and trying to shape that in the world that we want to see,” Brandt said.

“There are a lot of pillars of these trends that we’re experiencing now—things like advanced automation systems, additive manufacturing, new digital materials, and the list goes on.” But the ultimate question beyond identifying these trends is determining how they can be incorporated into Autodesk products, Brandt explained.

Although manufacturing has typically rested on the shoulders of those with big factories and big machines, Brandt sees certain technologies and social trends as the impetus to a paradigm change. With crowdsourcing options like Kickstarter, he noted that smaller businesses have more power than ever to fund their products. Couple that up with flexible, low-cost technologies like additive manufacturing, where a single machine can produce an infinite variety of products, and the result is a growing community of small to medium-sized manufacturers.

Of course, Brandt did mention the role that Autodesk has in offering more scalable and easy-to-use options to design these products, and considering the company’s recent adoption of a pay-as-you-go cloud model in Fusion 360, he wouldn’t be off-base.

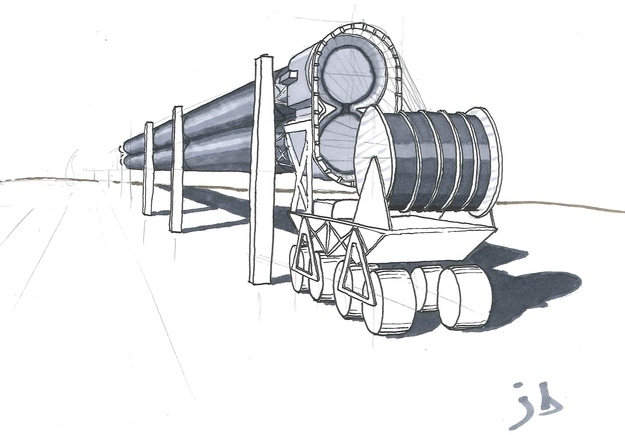

Using Autodesk’s new toolkit, Brandt has envisioned a manufacturing system that will create a bi-axial braid of fiber-reinforced polymer that is pinched into a figure eight design. This would stack the Hyperloop’s tubes to reduce the number of necessary support structures and ultimately save money from the manufacturer’s end.

Using Autodesk’s new toolkit, Brandt has envisioned a manufacturing system that will create a bi-axial braid of fiber-reinforced polymer that is pinched into a figure eight design. This would stack the Hyperloop’s tubes to reduce the number of necessary support structures and ultimately save money from the manufacturer’s end.

“We took a look at Elon’s proposal, and I think is fantastic that he’s willing to put himself out there and say ‘Here’s an idea, I know it might be flawed, but help me refine it,’” Brandt said. “Looking at it, we realized he had spent a lot of effort on the design of the capsules and the physics of how these vehicles move through the tube at very high speeds. And you would expect that from the founder of SpaceX and Tesla. But what we realized was that there wasn’t as much creativity put into the design of the infrastructure and the tubes themselves, which happen to be the most expensive aspect of this.”

“Looking at it, I realized there was a much better way to manufacture this,” he continued. “Instead of putting together section of steel tubes on a concrete pier and welding them together, what if we continuously braided this system.”

“Looking at it, I realized there was a much better way to manufacture this,” he continued. “Instead of putting together section of steel tubes on a concrete pier and welding them together, what if we continuously braided this system.”

Brandt explained that the braiding system would weave polymer resin and fiber into what is basically a giant Chinese finger cuff. The advantage here is a drastic reduction in seams, which are responsible for the majority of maintenance concerns as well as posing problems as far as seismic conditions—something California far from being free of.

But perhaps more importantly, the figure eight design would take up less space, which could give the train a slightly better point of leverage when it comes to what Brandt sees as the project’s greatest obstacle: land acquisition.

While the technology the braiding requires is by no means new, an effort of this scale that would take place outdoors where the Hyperloop would eventually travel presents a number of unique problems. Making the tubes requires what is essentially a giant, crawling sewing machine containing fiber spools, resin tanks, and the tools that weave them into a stack of tubes. But unlike existing machines of this type, the Hyperloop’s crawler must be ready to operate no matter what the elements throw its way.