A PIC for Bob

Build-A-Bearing

Do you know Bob?

Bob is the guy you see in the gym every morning, trying to sweat off his concerns about next month's payroll, energy bills, taxes, insurance premiums, and that contract with an everything-client that's about to expire.

Bob makes bearings.

His firm ("Bob's Bearings," you're thinking, but no; it's Rotational Science, Ltd.) boasts 244 engineers, operators, designers, salespeople and technicians who live and breathe bearings day in and day out.

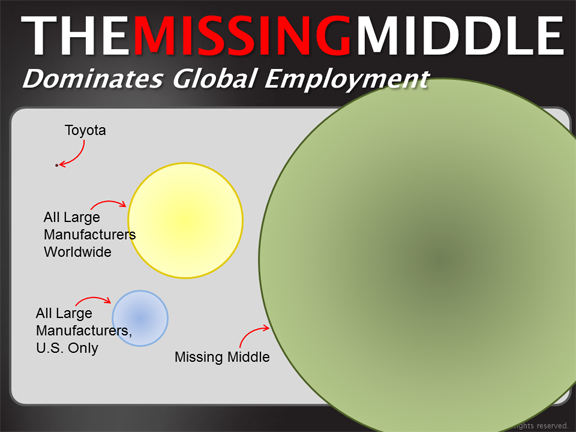

It occupies one of the two dozen outwardly-identical nondescript structures in Hickory Glade Industrial Park, which actually has no hickory glades but is close to an Applebee's. You know the place; you go by it every day. You might even work there. A lot of people work at Bob's, which is to say engineering and manufacturing firms that employ fewer than 500 people. With around 300,000 such outfits in the United States alone, it should come as no surprise that more than two-thirds of the total manufacturing workforce is employed by the Rotational Science, Ltds. of the world.

It occupies one of the two dozen outwardly-identical nondescript structures in Hickory Glade Industrial Park, which actually has no hickory glades but is close to an Applebee's. You know the place; you go by it every day. You might even work there. A lot of people work at Bob's, which is to say engineering and manufacturing firms that employ fewer than 500 people. With around 300,000 such outfits in the United States alone, it should come as no surprise that more than two-thirds of the total manufacturing workforce is employed by the Rotational Science, Ltds. of the world.

Bob would tell you — at length, and with considerable arm-waving — that the bearing is the unsung hero of modern society, tirelessly allowing things to move against other things, never demanding recognition or thanks. Without them the world would (literally) grind to a halt, because they're in everything, from shower curtain rings to medical lasers. And while to the layperson the bearing is probably "done" — there's little innovation left — that's not the case. Bob and his people have ideas that would change bearings so much whole product sectors could be revolutionized.

But there's nothing Bob can do, because small manufacturers like his rarely have access to the capital resources they need; those necessary to exploit innovation-driving technologies large manufacturers take for granted. Technologies like virtual manufacturing tools to create new designs and test them out. To model complex processes like material prototyping. To predict how world market fluctuations affect cost of raw materials. To build better bearings.

The Bobs of the country just need an avenue by which they can access and exploit modeling and simulation technologies to innovate faster, further, cheaper. The Bobs are where most innovations begin anyway. If only there was a way to turbo-charge it.

If only.

Off To the Big City

I admit that for most of my engineering career I didn't think about Bob. In fact, I didn't realize Bob existed. I graduated with my engineering degree, moved to the big city, and took a job at a big aerospace company. Later I switched to a big automaker. Buildings, people, facilities, computers — we seemed to have everything. Big manufacturers have the resources to do modeling and simulation.

Goodyear, of blimp and tire fame, leveraged a longstanding relationship with Sandia National Laboratory to develop software the company used on in-house hardware to run complex models. Product development time was cut from three years to one. It is amazing what a horde of Goodyear PhD engineers and the resources of a national lab can accomplish.

Bob would not say no to a 66 percent reduction in product development time.

Commercial planes these days are more than likely manufactured by Boeing or Airbus. Two very big manufacturers, with a lot of engineering and processing power at their fingertips. Both utilize software, centers, and hundreds of engineers provided by Altair, side by side with at least as many Boeing, Airbus, and supplier engineers to leverage tailored optimization methods, reducing the time to design and validate components by 50 percent, while reporting a 20 percent weight savings. Win-win!

Bob would greet lighter, more reliably-tested bearings with enthusiasm.

Anyone who's been around modeling and simulation knows the Pringles Story — how Procter & Gamble used modeling and simulation to redesign the famous chip's shape so the things would quit flying off production conveyors. But that is far from their only story. Lockheed-Martin is designing super-secret spy planes; Northrup-Grumman is advancing acoustics for submarines; Caterpillar is modeling dirt (hey, harder than it sounds, and if you're Caterpillar, darned important).

Procter & Gamble is quietly revolutionizing products designed to be pooped in.

Quantifying uncertainty in complex phenomena is not an easy task; harder even than modeling dirt. However, it was a science that Procter & Gamble deemed mission-critical as a savings mechanism for Pampers diapers. Thus the behemoth teamed with Los Alamos National Laboratory, applying LANL's advanced statistical models to P&G's vast datasets, rapidly developing and validating models. The result? More than a billion dollars savings in manufacturing efficiency of products designed to be pooped in and tossed.

Bob too would like to save a billion dollars. Heck, Bob would settle for a million.

These are examples of the power of modeling and simulation technologies from the largest companies. They all require massive computing power, customized software, teams of PhDs, and relationships with national labs.

Bob does not have these things. Bob has proximity to an Applebee's, and a very large responsibility: to keep the engine of the American economy firing on all cylinders.

My Bob Experience

Few American manufacturers have the kind of power we're discussing, and practically none are the Bobs, the small- to medium-sized manufacturers (SMMs) with fewer than 500 employees. I never grasped the criticality of this until my career took me to work for Bob.

Working for an SMM gave me a new vantage of both their importance and the innovative potential captive in our nation. When I started at this company — a custom chemical compounding supplier to the automotive industry — we had a new substance sitting out in our R&D area.

Imagine a material that expands, like bread in an oven (a car paint oven to be exact). It has the properties of concrete, but a fraction of its mass. Neat, huh? Heck, something like that, especially if it's cheap (it was) — the possibilities were endless! Just the safety benefits alone were enough to make the product a best seller.

So we left it on the shelf for three years.

Look, we didn't want to. We saw the potential. But it had no applied, validated purpose; no longitudinal testing data; no design. As such it had no customer. It was an unfinished dream.

Then, by collaborating with some very creative folks in R&D, adding my experiences in vehicle safety and some understanding of modeling and simulation, we penetrated the "we only buy things we can weld" world of automotive safety. Even then, though, it was painfully clear that the costs and testing to validate the designs would require a lot more than just simple engineering ingenuity. It would require modeling and simulation. Not only did my company not have the tools, but also, like all SMMs, we didn't have the free capital on hand for a huge investment. If we were going to do it, we had to do it in a way that made sense for an SMM, not a Boeing or Procter & Gamble.

We had to start small but evolve big, and the key was a progressive and aggressive management team. They saw the potential and were willing to invest, but only if it was done smart. The company purchased a four-core machine and some pretty basic linear simulation tools. As that computing power began to pay dividends, we eventually graduated to a dedicated 48-core cluster with associated software and personnel. It was more than paying for itself — way more, to the tune of doubling our sales — but we'd hit a sort of SMM wall, too. We had evolved to this point, but the next steps threatened to exceed our grasp.

As opportunities continued to mount, resources were in high demand. Justifying the expansion beyond the resources at hand was becoming more and more difficult. We had to turn away business that would have been lucrative, but not lucrative enough to justify another major boost in our internal modeling and simulation capabilities. We realized the best solution would be a place where hardware and software could scale up or down as needed.

There had to be something like that out there, right?

For months I searched.

Then one afternoon, sitting in our Shanghai office (many SMMs are required to go global today to keep in touch with their global customers), Google landed me at the website for the National Center for Supercomputing Applications (NCSA) at the University of Illinois. They had a private sector program that looked a lot like a solution. Hallelujah! I was soon Illinois-bound. And while the NCSA's unbelievable capabilities were not quite ideal for my company's needs at the time, I discovered another treasure on that trip, and it changed everything.

On the south side of campus, during a tour of the University of Illinois Research Park, I had the opportunity to visit Caterpillar's Simulation Center (where they model dirt). Around 100 people, some full-time Caterpillar and some students, coming and going as schedules permitted. They were problem-solving for Caterpillar design facilities, performing simulation work on new machine concepts and developing software tools used to design products. If you were at Caterpillar and had a problem, this center was where you went to get it solved.

That's when I got an idea.

Wouldn't it be cool if my company could start a scaled-down version of this simulation center? Not 100 employees, maybe two or three. Hire a couple of part-time students and grow a simulation center.

Awesome? Yes! Practical? No. Approved by the boss? Absolutely not!

If I couldn't justify the ROI for expanding our internal resources in Michigan, how could I justify a new offsite facility? By this time my company had grown to over 700 employees worldwide and technically was no longer an SMM. We were growing and business was booming, yet convincing management to add further resources was becoming more and more difficult. If we could not justify the investment how could the typical SMM? How could Bob?

Then I had another idea, one borne out of the wins my company had seen in its early collaborations to launch the new material, and fueled by what I saw at the Caterpillar Simulation Center.

What if Bob shared a center with all the other Bobs? Bob could come and go as his needs dictated and pay for the resources he needed, when he needed them. What about a collaborative hub that incorporated timesharing and an Apple App Store-like spectrum of capabilities, so any SMM could find the tools they needed? Bob could use modeling and simulation to create the perfect bearing, while Bob could use it for dirt, and Bob could virtually prototype a new product. And they'd all only pay for the power and time they needed.

This fell outside my current employer's core competencies and business strategy. However, the idea continued to percolate, and it wouldn't leave my mind. Moving to the National Center for Manufacturing Sciences (NCMS), I found that similar ideas were simmering. SMMs desperately need powerful new tools, and NCMS is the only place that can manage such ambitious national collaborations. And at NCMS, what began as "Wouldn't It Be Great If" grew into a strategy for a nationwide network of Predictive Innovation Centers, or PICs.

A PIC for BOB

Let's say you work for Bob, one of those tireless SMMs. 90 percent of you have no capabilities beyond what you can do on your desktop PCs. You're certainly not staying up at night figuring out how you're going to buy that computing cluster, or pay for the required software licenses, or lure that PhD away from Boeing to come work for you.

You didn't even know these tools existed!

Or you read an article once, but you make elevator cables and that article was about this auto chassis manufacturer and those are totally different worlds.

Or you don't need it, because you've done fine so far.

Or you want it, but doing it in-house doesn't make sense from an ROI standpoint.

Or you'd like to check it out, but...supercomputers in the basement? The other office drones will lynch you.

Or you do have some HPC capability, but you're really not using it to the degree it could be used.

Well, your kid has a six-core gaming PC at home, and you know how hard those things cook during a game, but it hasn't exactly been a CAE powerhouse for you.

No problem. At least, it won't be, once the PIC network is there.

Awareness? We're on it. I guarantee, once we're done, you'll know that the capability exists, you'll know how to use it, you'll know what it can do for you, and you'll know why it will energize your business like a badger on chocolate espresso beans.

Cost? Forget it. PICs eliminate the need to establish in-house capability. You pay based on core-hour, which is a fancy way of saying the amount of time and amount of computing muscle you want, on a job-by-job basis.

That PhD? Your own people are fine, though you'll soon be growing and hiring. The PICs will provide plenty of e-Learning, and the tools are available through secure, Web-based portals. And the PICs themselves will have expertise you can leverage.

The PIC strategy is a pretty simple progression:

A. Make SMMs aware of the need and provide necessary education.

B. Drive massive adoption by making the tools easy to get at.

C. Encourage ever-further use and integration into business models.

Everyone is happy, because it's a collaborative effort. Collaboration eliminates many cost and risk barriers. SMMs can't buy huge HPC clusters. And PICs don't need to: they're all around us. National labs, universities, and plenty of others have tons of available computing bandwidth, live expertise, and a desire to see modeling and simulation grow. No one or two can do it alone, and without a proven collaborative model it's doomed. That's where NCMS comes in.

The strategy facilitates upward progression, so users can elevate to a self-sustaining modeling and simulation capability if they want to. It's part timeshare, part App Store, part teamwork.

I will readily admit that none of these three components are novel in their own right. Timesharing of computer resources has been around for almost as long as computers. Smartphones ushered in the era of the "App Store" several years ago. And if you don't know about NCMS, well, you should — call me!

Let's break these three down.

Timeshares and App Stores

Timeshares get a bad rap. I own a Marriott timeshare on Oahu and I love it, though I realize not everyone likes the model. I remember a story a lawyer told me: an elderly client was unable to sell a timeshare her husband had bought as an anniversary present before his passing. She wound up willing it to a family member who'd crossed her years before — the inheritance that kept on taking. Like a gym membership, you only get value out of the time-share concept if you use what you've paid for.

But unlike a real estate timeshare, in the PIC case you're leasing and aren't shackled to power you don't always need. You pay a fraction of the overall cost for something that would be otherwise out of your price range, in exchange for periodic access. Cost-sharing addresses one of the fears of up-front investment. Suddenly Bob doesn't need to buy a cluster, he can time-share one. And in doing so he'll get access to a cluster thousands of times more powerful than what he could manage on his own. Remember, my smallish employer bought four cores and we thought we were the cat's pajamas (which, to be fair, in 1997 was not far from true).

Four cores? Bob, Bob, Bob. Take your four cores. I'll raise you 250,000 from the data gobbling terror that is a national laboratory's massively parallel supercluster, a chunk of which might be yours through a PIC's collaborative agreement.

But Bob does bearings. He needs modeling and simulation for all kinds of friction calculations, fluid dynamics, turning ratios. Where are we without the software?

Enter the app component. We're well aware of the enormous success of Apple's App Store. The best stuff naturally rises to the top, and no matter what your need, sooner or later you're going to find an app for it. A percentage of revenue to Apple, a majority to the developer, everyone is happy. Last I checked there are almost 500,000 apps available at Apple's App Store and over ten billion downloads. Apps to enhance productivity and apps to waste time, and just about everything in between. As the number of apps has grown so has the number of downloads. Talk about a self-sustaining business model!

Wouldn't it be cool to create apps that manufacturers could easily access and use? Not quite an Apple App Store, but we can learn from the model. Apps that become the simple user interface to these newly-available timeshared capabilities. Plenty of manufacturing-worthy HPC apps already exist, and we can broaden their reach while encouraging the development of more — something that will fuel even more high-tech employment.

The key to the PIC concept is that it be made available to every Bob in the country. It eliminates the key barrier to entry: that no one can do it alone — or, at least, no one should have to. Commercialization and training are therefore part of the strategy. An impartial collaborative manager must protect IP, organize access to apps, develop training for new users, and build awareness of the need.

Collaborate, Innovation, Commercialization

The future belongs to organizations that collaborate to out-compete. Collaboration begets innovation, which begets commercialization — and these three concepts form the PIC philosophy.

A century ago, the electric power infrastructure was key to a strong manufacturing base. Today, a national network of high performance computing clusters is critical to the future of American industry. Economic uncertainty and leaden growth have slowed innovation, but access to cutting edge tools, resources and capabilities provide a bold path forward, essentially transforming the way America builds. The opportunity is now. High performance modeling and simulation is a key American asset, and they provide a distinct competitive advantage for each and every SMM.

A century ago, the electric power infrastructure was key to a strong manufacturing base. Today, a national network of high performance computing clusters is critical to the future of American industry. Economic uncertainty and leaden growth have slowed innovation, but access to cutting edge tools, resources and capabilities provide a bold path forward, essentially transforming the way America builds. The opportunity is now. High performance modeling and simulation is a key American asset, and they provide a distinct competitive advantage for each and every SMM.

Ten years from now, the global manufacturing sector will look nothing like it does today. It's time for a bold, new direction for US competitiveness, capitalizing on smart manufacturing as a strategic asset for growth.

Bob's right: bearings are more important than we realize.

Bearings bear things. Just like Bob. Small- and medium-sized manufacturers hold up economies, and economies are heavy.

Let's give 'em all the gym time they need to stay nice and strong.